| Sign In | Join Free | My components-electronic.com |

|

| Sign In | Join Free | My components-electronic.com |

|

| Categories | Paper Roll Wrapping Machine |

|---|---|

| Brand Name: | FEXIK |

| Model Number: | F-T8 |

| Certification: | ISO9001/CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | USD 240000-270000 USD/SET |

| Payment Terms: | T/T |

| Supply Ability: | 15 sets/year |

| Delivery Time: | 120-150days |

| Packaging Details: | standard package for sea shipping |

| Usage: | to pack paper roll in tissue paper production line |

| Production speed: | 90 packs/min |

| Infeed: | 3-4 lanes |

| Layers: | 1 and 2 layers |

| Average format changeover time: | 35 min |

| Roll diameter: | 90-160(200)mm(3.5”-6.3”)(7.9”) |

| Roll length: | 90-300(3.5”-11.8”) |

| Pack width: | 100-650mm(3.9”-25.6”) |

| Pack length: | 90-630mm(3.5”-24.8”) |

| Pack height: | 90-270mm(300mm) (3.5”-10.6”)(11.8”) |

| Power supply: | 380Voltage |

| Air Consumption: | <500 L/Min |

| Wrapping Material: | PE,LDPE printed film roll |

| PE thickness,LDPE: | 45 microns |

| Real Power consumption: | 35KW |

Tissue paper production line paper roll wrapping machine

1. Machine Appearance

This is our latest and technologically most advanced machine for packaging toilet and kitchen towel rolls with a wide range of packaging configurations.

2. General Description

The wrapper is used for packaging maxi rolls, toilet tissue and kitchen towel rolls. The packing material is plastic film, PE or others.

| Name | Technical Parameters |

| Production speed | 35-140 packs/min |

| Max mechanical speed | 160 packs/min |

| Infeed | 1-5 lanes |

| Layers | 1 or 2 layers design |

| Average format changeover time | 10-30 min |

| Roll diameter | 90-160(200)mm(3.5”-6.3”)(7.9”) |

| Roll length | 90-300(3.5”-11.8”) |

| Pack width | 100-650mm(3.9”-25.6”) |

| Pack length | 90-630mm(3.5”-24.8”) |

| Pack height | 90-270mm(300mm) (3.5”-10.6”)(11.8”) |

| Power supply | 380V 50HZ/60HZ |

| Air Consumption | <500 L/Min |

| Wrapping Material | PE,LDPE |

| PE thickness,LDPE | 25-50 microns |

| Real Power consumption | 32KW |

| Machine weight | About 8000kg |

3. Main Features and Advantages

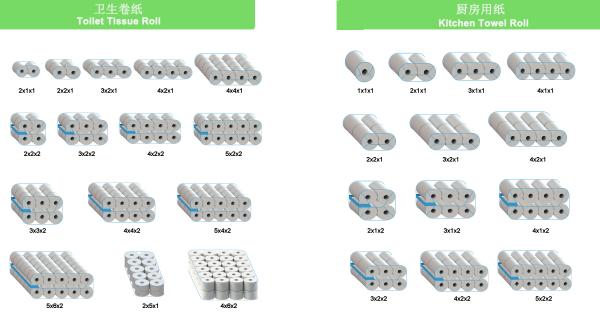

1) The double-layer wrapping equipment allows a wide range of packaging configurations for toilet roll and kitchen towel. Full automatic and high speed multiple-pack film packing machine for toilet roll and kitchen towel with 1 or 2layers.

2) This wrapping machine is easy to run and maintain, fully servo driven and controlled by the most advanced motion controller SIMOTION D, which provides an reliable production processing.The production speed can reach to 140 packs/min which meets customers the leading edge for high quality package in high speed demand.

3) User friendly Human Interface with help of operation & changeovers, variety of packaging configurations are optional. This wrapper is designed have many kinds of packing configurations according to customers’ requirements.

4) Optional for 5 lanes infeed function and vertical toilet rolls configuration.

5) Selecting bearings, reducers, guide rails, sliders, and various photoelectric are chosen from the world's well-known brands. At the same time, rugged components are used in all areas to reduce vibration and ensure long-term reliability

6) This wrapper can pack perfectly even running in high speed.

7) The use of motor adjustment is convenient and quick, providing an extremely easy and quick format changeover.

4. working principle

The rolls are coming by five channels conveyor; they are launched in the number of lanes according to packaging configuration needed, which is set by HMI, in the single layer or double layers into in-feed section, where they are transported and stacked by group of carbon bars mounted on trimming belts. Carbon bars convey the group of rolls on the elevator, which leads them into the area of folding. The foil positioning section brings the packaging film directly above the rolls by transport belts. The folding process is performed by universal side folders, as well bottom folder and counter folder. Side folding is done by innovative air supported mechanical folders. The overhead pack transport section continuously moves the pack through section of side folding and rotating bottom sealer and deliver pack to side sealing section. All motions and functions are fully controlled by the 21 independent servo motors and 6 inverter motors.

5. Conveyor design

Four-channel motorized belt conveyor, about 4meters long, controlled by inverter, for rolls accumulation.

The group includes series of photo-eyes sensors for controlling the right position and the presence of rolls.

welcome to contact us!

|