| Sign In | Join Free | My components-electronic.com |

|

| Sign In | Join Free | My components-electronic.com |

|

| Categories | CNC Turning Parts |

|---|---|

| Brand Name: | WINS TECH |

| Model Number: | WCMP193 |

| Certification: | ISO 9001:2015, ISO 14001, IATF16949:2016 |

| Place of Origin: | China |

| MOQ: | No MOQ |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 100k per month |

| Delivery Time: | 1~5 days |

| Packaging Details: | standard air packing |

| Application: | Machine Parts,Home appliance equipment,Auto parts,Industrial equipment |

| Process: | CNC Machining,Machining/Turning/Drilling/Grindling |

| Equipment: | CNC Machining Centres,CNC Lathe Machines |

| Color: | Customer's Demand |

| Surface treatment: | anodizing,electroplating,powder coating,Thermal treatment,Painting |

| Finish: | colour anodize,sandblasted,polished,chrome plating,nickel plating |

| Company Info. |

| Shenzhen Wins Tech Limited |

| View Contact Details |

| Product List |

Wins tech limited is a China CNC precision machining manufacturer and Chinese CNC machining company with state-of-the-art CNC manufacturing factory based in China. We provide custom 3-5 axis CNC machining services, CNC Milling Services, CNC Turning Services, CNC Grinding Services, Wire EDM Machining and manufacture CNC machined parts, CNC milled parts and CNC turned parts in our China precision CNC machining factory.

Wins tech limited has been providing quality service to the CNC precision parts industries for over 12years. Wins tech has rapidly earned the confidence and trust from our customers through outstanding quality of work and professional service that is emphasized through every product.

Wins tech limited has been engaged producing and supplying all kinds of CNC Milling parts over 12 years. Our flagship products include Brackets, Covers, Housings, etc. Conforming to all customer’s prints and the tolerance standard: ISO2768m, ISO2768f. These product supports a variety of applications, including chemical equipment, automotive industry, consumer electronics, etc.

Except CNC machining, we also provide one stop solutions like heat treatment, finishing, assembly and inspection.

Wins tech limited offers a wide range of custom micro CNC machining services, including 3, 4, and 5-axis CNC milling and CNC turning, grinding, EDM, laser cutting, and others. There are abundant CNC machining services from design, rapid prototyping, and complex parts geometry to low or large-volume production for your choice. And we are always committed to producing high-quality machined parts in line with your budget and lead time demand.

What is CNC Turning?

CNC Turning is a manufacturing process in which bars of material

are held in a chuck and rotated while a tool is fed to the piece to

remove material to create the desired shape. A turret (shown

center), with tooling attached is programmed to move to the bar of

raw material and remove material to create the programmed result.

This is also called “subtraction machining” since it involves

material removal. If the center has both tuning and milling

capabilities, such as the one above, the rotation can be stopped to

allow for milling out of other shapes.

The starting material, though usual round, can be other shapes such

as squares or hexagons.

Depending on the bar feeder, the bar length can vary. This affects

how much handling is required for volume jobs.

CNC lathes or turning centers have tooling mounted on a turret

which is computer-controlled. The more tools that that the turret

can hold, the more options are available for complexities on the

part.

CNC turning (also known as CNC lathes) is a subtractive manufacturing process in which a stationary cutting tool removes material by making contact with the spinning workpiece to create the desired shape.

During processing, a blank bar of stock material is held in the chuck of the spindle and rotated with the spindle. Extreme precision and repeatability can be achieved under the control of computer instructions for the movement of the machinery.

When CNC turning rotates the workpiece in a chuck, it’s generally to create round or tubular shapes and achieve far more accurate rounded surfaces than CNC milling or other machining processes.

Customer Ever Said:

. I want to say that your products are very good. Thank you for all your suggestion, also good after sales service. -- Adela

. We trust the quality of your products. It always the best. Keep this going, and we will establish a long-term trade relationship with you. -- Charlie Bingham

. It has been more than 2 years we worked together, we are very happy working with them.--MICROTEX INC.

. Their products are very good,I trust this company.--RICHARD ENGSTROM

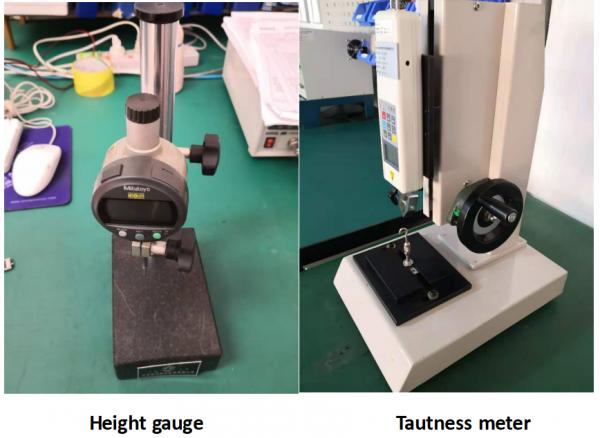

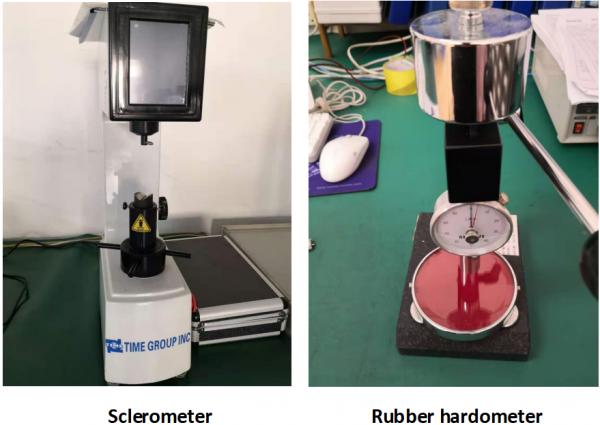

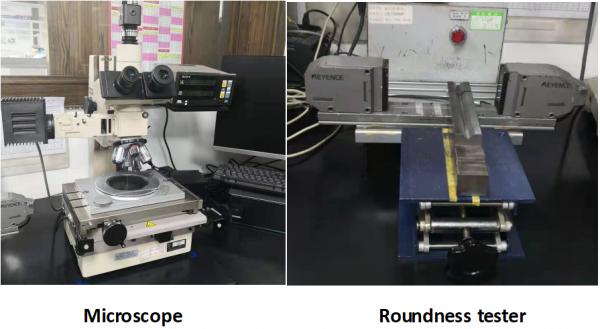

WINS TECH LIMITED EQUIPMENT LIST | ||||||||

| Item | Classes | Equipment | Brand | Quantity | Unit | Service time | on state | Notes |

| 1 | General-purpose machine tool | Miller | Jaguard | 3 | set | 2 years | under normal service conditions | |

| 2 | Jaguard | 3 | set | 2 years | under normal service conditions | |||

| 3 | Foshan machine | 1 | set | 2 years | under normal service conditions | |||

| 4 | Turning-lathe | Guangzhou Nanfang | 1 | set | 2 years | under normal service conditions | 6140D | |

| 5 | Digital controlled lathe | CNC lathe | Taihe | 6 | set | 2 years | under normal service conditions | 46 line cutter machine |

| 6 | 4 axis precision automatic lathe | SUPVAN | 3 | set | 2 years | under normal service conditions | ||

| 7 | 5 axis precision automatic lathe | NONO | 3 | set | 2 years | under normal service conditions | ||

| 8 | Digital controlled lathe | CNC machining center | 4 | set | 0.1 year | under normal service conditions | 850H | |

| 9 | CNC machining center | Xin Tenghui | 1 | set | 2 years | under normal service conditions | 1280H | |

| 10 | CNC machining center | Xin Tenghui | 1 | set | 2 years | under normal service conditions | 750H | |

| 11 | CNC machining center | J-Y CNC | 3 | set | 2 years | under normal service conditions | 650H | |

| 12 | CNC machining center | DeMarco | 2 | set | 1 year | under normal service conditions | 2150H | |

| 13 | CNC machining center | 2 | set | 2 years | under normal service conditions | 46 line cutter machine | ||

| 14 | CNC lathe | Taihe | 8 | set | 1 year | under normal service conditions | 46H | |

| 15 | Cutter tower turning milling compound machine | 1 | set | 0.5 year | under normal service conditions | 46H | ||

| 16 | CNC turning milling compound machine | Taihe | 3 | set | 1 year | under normal service conditions | 325-355 | |

| 17 | Line cutting equipment | wedm-ls | SODICK | 3 | set | 5 years | under normal service conditions | 500H |

| 18 | wedm-hs | Changan | 2 | set | 1 year | under normal service conditions | 540H | |

| 19 | wedm-hs | Taizhou | 2 | set | 1 year | under normal service conditions | 540H | |

| 20 | Auxiliary equipment | hand drilling machine | 1 | set | 1 year | under normal service conditions | ||

| 21 | perforating machine | 1 | set | 1 year | under normal service conditions | |||

| 22 | tapping machine | 2 | set | 1 year | under normal service conditions | |||

| 23 | chamfering machine | 2 | set | 1 year | under normal service conditions | |||

| 24 | sharpener | 2 | set | 1 year | under normal service conditions | |||

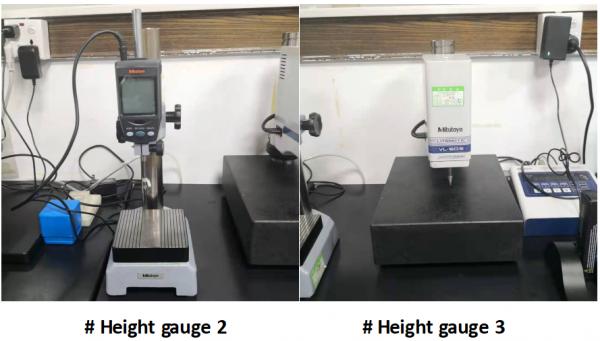

| 25 | Inspection equipment | height gauge | 3 | set | 1 year | under normal service conditions | ||

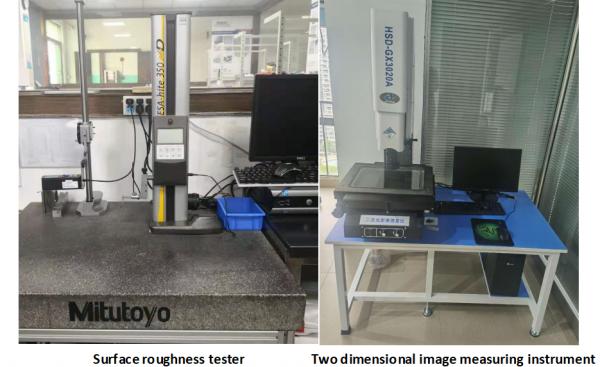

| 26 | Two dimensional image measuring instrument (YVM) | 1 | set | 1 year | under normal service conditions | |||

| 27 | Three dimensional detection | 1 | set | 1 year | under normal service conditions | |||

| 28 | Surface roughness tester | 2 | set | 1 year | under normal service conditions | |||

| 29 | tensile machine | 2 | set | 1 year | under normal service conditions | |||

| 30 | sclerometer | 2 | set | 1 year | under normal service conditions | |||

| 31 | microscope | 1 | set | 1 year | under normal service conditions | |||

| 32 | True roundness detector | 1 | set | 1 year | under normal service conditions | |||

» Sample & Mold

Q : Can i have a trial order or samples only for several pieces?

A : As the product is customized and need to be produced, we will charge sample cost, but if the sample is unqualified, the sample will be free or after you placed mass orders, we will refund the sample cost.

Q : Can you open mold for us to manufacture new product?

A : Yes! if the quantity is big, our company can afford part of the mold cost.

» Delivery time & after-sales service

Q : Can you provide after-sales services?

A : Generally it is 20 -30 days after the drawing confirmed.

Generally it is 20 -30 days after the drawing confirmed .

Q : Can you open mold for us to manufacture new product?

A : Yes, every defected products will be replaced and the cost be

responsible by us or we will send new ones to customer immediately

if it is urgent. However, it would take some time for the first

production and almost 0 bad feedback from our customers after then

.

» Payment Terms

Q : What is your terms of payment?

A : T/T(For big order, 30-90 days can be acceptable)

» About quotation

Q : How can i get the quotation?

A : Please send us information for quote; drawing, material,

weight, quantity and request, we can accept PDF, ISGS, DWG, STEP

file format.

If you don’t have drawing, please send the sample to us, we can quote base on your sample too.

Quality inspection:

Zero defect rate target, automatic inspection equipment;

One-stop customized manufacturer accept all kinds of materials;

About WINS TECH LIMITED:

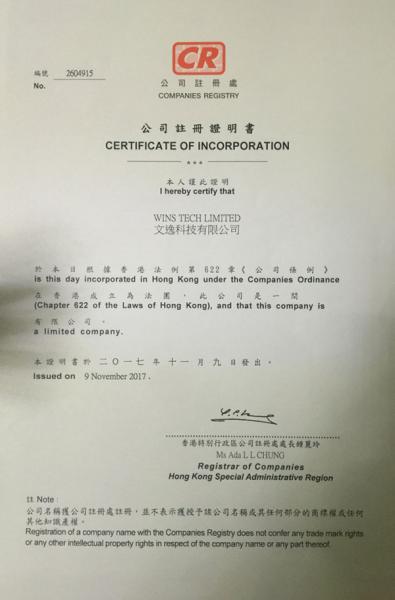

· March, 2012: WINS TECH LIMITED Set Up

· October, 2014: ISO9001 Certificate

· September, 2017: WINS TECH LIMITED HongKong branch office Set Up

· December, 2017:start to expand overseas markets

· May, 2019: 2 automatic production lines set up, 4 production lines in total, factory production capacity over 1 million

· May, 2020: ISO14001 Certificate

· September, 2021: IATF16949 Certificate

· 2022~ : to be continue

Certifications

Wins tech limited guarantees the quality of your machined parts with our ISO 9001:2015, ISO 14001, and IATF16949 certified quality management system, ITAR registration , and options to add inspections, hardware traceability, material certifications, and CoCs. We accept technical drawing and have support teams to ensure you get quality CNC machined parts on time.

High speed fabrication and prototyping!

We accept OEM and ODM, customizable!

We warmly welcome clients from all over the world to come to our

factory for visit and cooperation!

|