| Sign In | Join Free | My components-electronic.com |

|

| Sign In | Join Free | My components-electronic.com |

|

| Categories | Precision CNC Machining Parts |

|---|---|

| Brand Name: | OEM/YMP |

| Model Number: | YMP01103 |

| Place of Origin: | Shenzhen, China |

| MOQ: | 100 |

| Price: | $0.347-0.351 piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 pieces per day |

| Delivery Time: | 7 days |

| Packaging Details: | Inner pearl button, outside carton box, or customized |

| CNC Machining or Not: | CNC Machining |

| Type: | Broaching, DRILLING, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

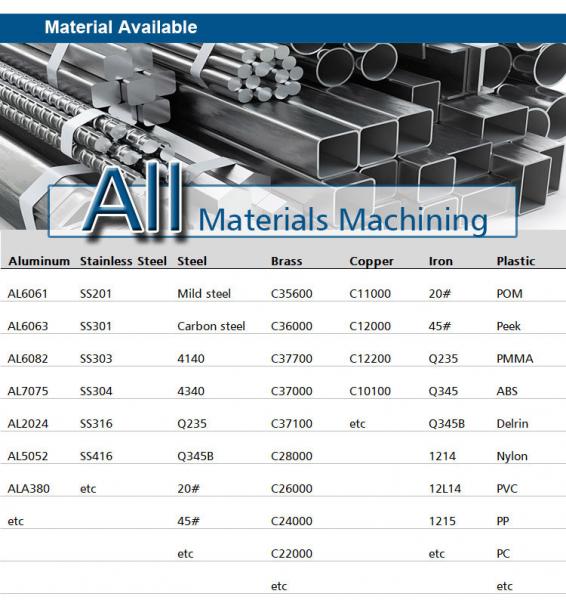

| Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, POM |

| Micro Machining or Not: | Micro Machining |

| Materials Avaliable: | Aluminum Stainless Plastic Metals Copper |

| production name: | customized CNC mechanical parts |

| Service: | OEM\ODM |

| operation: | CNC machining,die casting,stamping,injection |

| MOQ: | 1 piece |

| certifiocation: | ISO9001:2015 |

| Quality control: | 100% Inspection |

| Size: | Custom Requirement |

| Sample: | within 5 days |

| tolerance: | +/-0.005mm |

Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

Usage: | Agricultural machine,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

Tolerance: | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized, anodize, electrophoresis and others. |

Color: | Optional with various colors as required by customer. |

OEM: | Yes, can produce based on customer's drawings or samples. |

Lead time: | 15-20days for mold and 30days for first lot. |

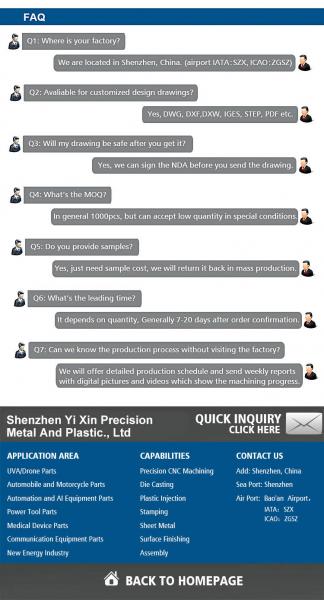

Answer: The minimum order quantity is subject to business communication and negotiation, and the proofing fee is usually more expensive than the price of bulk goods, because it is impossible to ask the material supplier to cut a small piece by pieces when loading materials, and it is impossible for CNC wire cutting programming to be as convenient as mass production.

Answer: Every factory has its operation mode. Although the mechanical processing equipment is similar, the workmanship and sense of responsibility are quite different. The price-performance ratio can't be defined simply by the price or scale. Any product that deviates from the quality and service is a one-shot deal and won't last long. We only make the best products, receive every customer with the fastest and best service, and make every customer our long-term customers.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

|